Mono Layer Line-OSC

Mono Layer Line-OSC

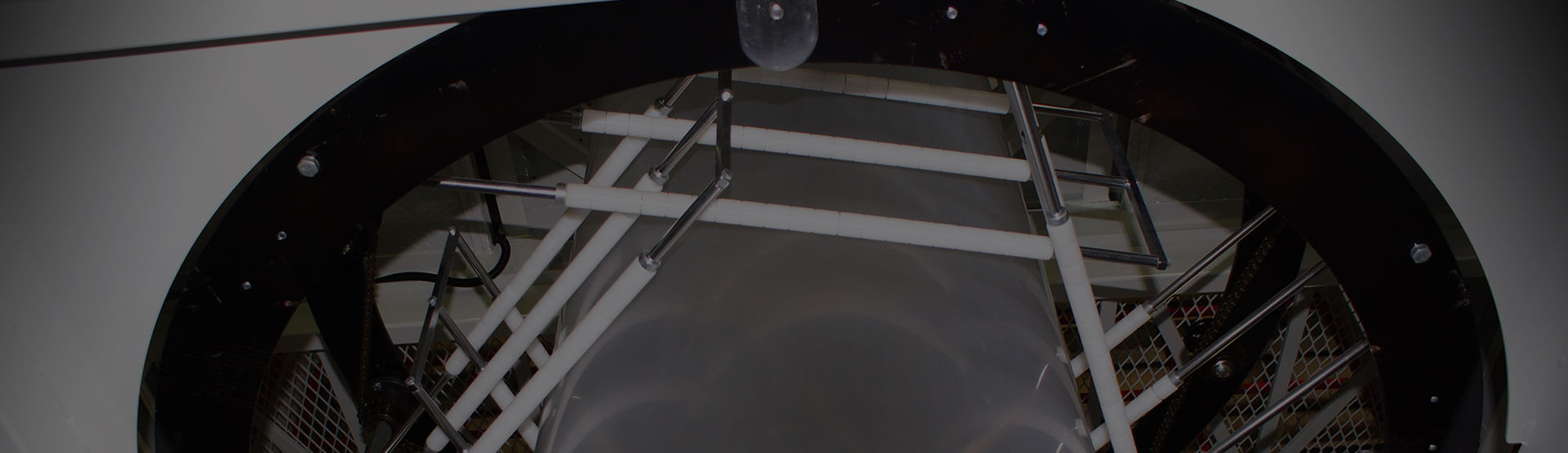

Single Layer LDPE Blown Film Machine with Oscillating Take-Off Unit

SE/LD-LLD-65-1300/1600 OCS

- Introduce the latest design idea.

- Adopt the safety protection design for the whole device.

- It could be reduced the electricity loss more effective when equipping the inverter control in the whole device.

- Professional, Technology, Service & Quality are doing firstly for us.

- We are the professional manufacturer and experience supplier for blown film machine.

- The air from the air ring is stable. The air ring can be designed for single, two layers, and three layers as per requirement.

- Fixed ring is controlled by electric and easy operation and practical utility.

- Collapser has two types, steel roller and latticed wood. It also can use both which has patent to ensure film quality better.

- Winding unit operated by computer screen, full automatic cutting and bobbin change with tension control and connected with take-off unit to get more stable and practical operation at the same time.

| Model | SE/LD-55OCS | SE/LD-65OCS |

| Film width (mm) | 1200 | 1500 |

| Film thickness (mm) | 0.02 - 0.15 | 0.02 - 0.15 |

| Extrusion output (kg/hr) | 80 | 130 |

| Extruder | ||

| Diameter (mm) | 55 | 65 |

| L:D ratio | 30╱1 | 30╱1 |

| Drive motor (hp) | 40 | 56 |

| Heat capacity (kW) | 65 | 101 |

| Temperature Control (zones) | 6 | 6 |

| Die | ||

| SCREEN CHANGER | LONG LIFE FILTER | |

| Lip diameter (mm) | 250╱300 | 250╱350 |

| TAKE-UP UNIT | ||

| Drive motor (hp) | 2 | 2 |

| Roller width (mm) | O210×1300 | O210×1600 |

| GUIDE MOTOR (hp) | 2 | 2 |

| Take-off unit (with elevator) | ||

| Drive motor (hp) | 2 | 2 |

| Roller width (mm) | O165×1300 | O165×1600 |

| Winding unit | ||

| Floor dimensions (m) | 11.3 x 3.4 x 7.1 | 12 x 3.8 x 9.1 |

| Machine weight (kg) | 7500 | 8500 |

| Power required (kW) | 70 | 100 |