ABC 3 Layer Line

ABC 3 Layer Line

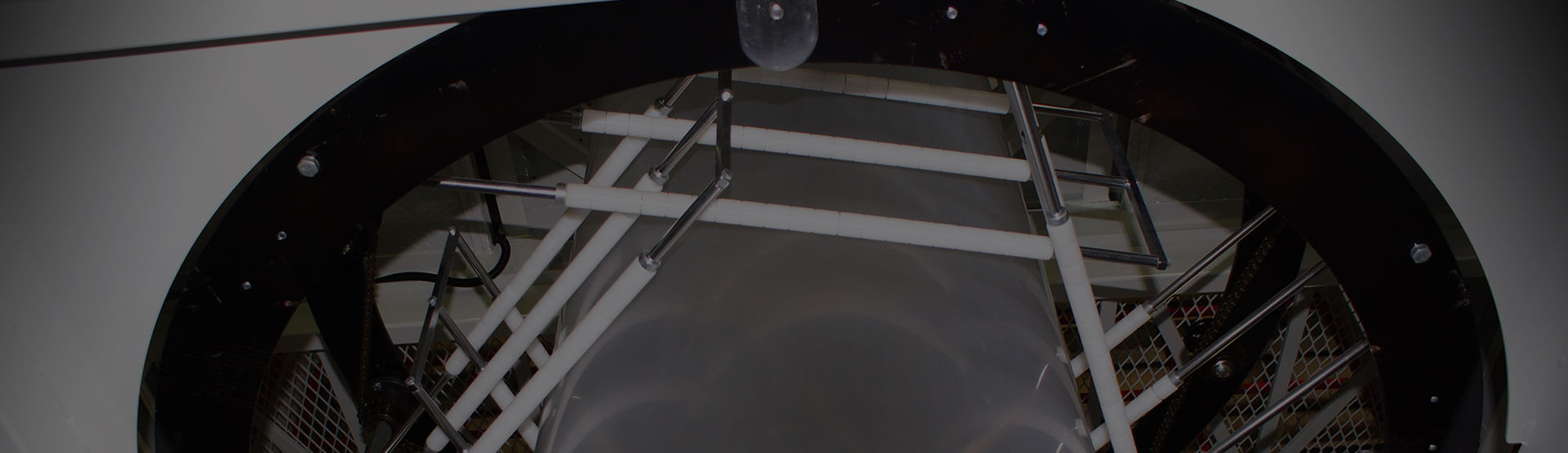

A/B/C Triple Layer LD/LLD Blown Film Machine With Oscillating Take-Off Unit

SE/LD/LLD-55-65-55-1300/1600/1800-OSC

- Reduce the cost of raw material.

- Combine the properties of the different raw material.

- It could get uniformly thickness of the film when it equips the oscillating take-off unit.

- Percent value of material could be controlled more effective in each layer by equipping the volumetric dosing device.

- When adopting the latest design of the automatic winder and equipping the tension control device, it could be controlled more precise in the winding.

- We are the professional manufacturer and experience supplier for multi-layer blown film machine.

- This machine could be combined different characteristics of plastic raw material in the same work.

- Oscillating take-off unit is driven by gear transmission.

- The gear transmission which is well precision and good stability can make the film more uniform of the thickness. Its rotational angle could be attained to 360°. It could be equipped the EPC device which could be controlled to get neat edge for film in the winding.

- Auxiliary take off motor is stably driven with SERVO motor.

- The tensility is controlled by low friction cylinder.

- The bubble film could be covered approach of circle with intersection type of fixed ring.

- We are the professional manufacturer and experience supplier for multi-layer blown film extrusion.

| 65-55-55MM TRIPLE LAYER HDPE/ LDPE BLOW FILM MACHINE WITH OSCILLTING TAKE-OFF UNIT | |||

| MODEL | SE/HL-65-55-55-OSC | ||

| MATERIAL | HDPE/ LDPE/ LLDPE | ||

| OUTPUT | 120-140 KG/HR | ||

| EXTRUDER | SINGLE TYPE | ||

| DRIVE MOTOR | 75 HP + INVERTER | 1 SET | |

| SPEED RANGE | 50 HP + INVERTER | 2 SET | |

| SCREW DIAMETER | STEPLESS | ||

| L/D RATIO | 55 MM | 1 SET | |

| TEMP. CONTROL | 20 ZONES | ||

| DIE | TYPE | TRIPLE LAYER A/B/C DIE | |

| LIP DIAMETER | Ø200/ 250 MM | ||

| COOLING UNIT | AIR BLOW | 10 HP + INVERTER | |

| AIR RING | TYPE | TRIPLE LAYER | |

| MATERIAL | ALUM. CASTING | ||

| DOUBLE WINDER | TYPE | BACK TO BACK BY FULL AUTOMATIC | |

| CONTROLLER | PLC CONTROL SYSTEM (HMI TOUCH SCREENS) | ||

| WINDING WIDTH | 1100 MM | ||

| DRIVE MOTOR | 2 HP + INVERTER | 2 SET | |

| BOBBIN CHANGE SYSTEM | FULL AOTUMATIC | ||

| WINDING ROLLER | PNEUMATIC TYPE | ||

| SLITTING DEVICE | CYCLIC PNEUMATIC SLITTING KNIFE TWO-SIDE SLITTING | ||

| FLOOR DIMENSION | 12.0 × 3.8 × 10.0 M | ||

| MACHINE WEIGHT | 12003 KG | ||

| POWER REQUIRE | 170 KW (APPROXIMATELY) | ||